Will Indian industry come close to Japanese Quality?

There are many cynics when it comes to Indian manufacturing and quality. Will we ever get to ultra-high quality, precision engineering, artistic designed products? Yes. Let me explain why.

I read recently how Japan is good at many things. Japan is winning - from best Pizza restaurants, pastries, confectionaries, wines and whiskey to best crafted shoes, jeans, to cars and watches and more.

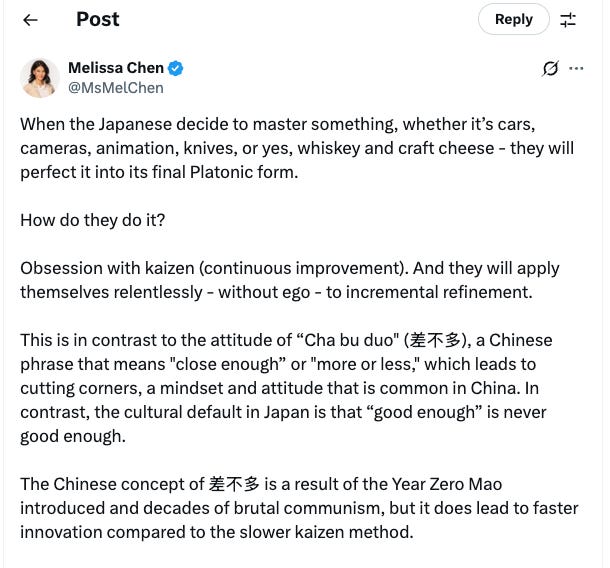

Melissa Chen commented on this, contrasted this with the Chinese attitude of “Cha bu duo” (差不多), a Chinese phrase that means “close enough” or “more or less,”. Many commentators have taken similar line when it comes to Indian “jugaad” culture. The understanding is Chinese or Indian excellence will not be like the Japanese.

But it is not true.

The industrial culture developed with different styles across the world.

At first there were two routes - mass manufacture and artisanal manufacturing. Britain and US followed the mass manufacturing route. France and Italy chose the artisanal manufacturing. Germans tried to bring artisanal qualities to mass manufacturing, their focus was artisanal when it came to engineering and design but it was mass manufacturing mindset when it came to operations. That is why design, innovation etc. seemed separate from cold, calculating Operations.

When Japan entered the fray, they tried to imitate this. But failed. Rather Demming, Juran and their Japanese counterparts from Ishikawa to Ohno to Taguchi experimented with adapting the western concepts to Japanese culture. The result was exceptional Japanese Industrial renaissance.

Japanese made the operators into craftsman/artists. Japanese art culture is blend of discipline and rules with flair and Iki (a japanese word difficult to translate - more like flirting beyond the no-go rules). It allows for these artists in operations. But such artists also become masters and can blend into engineering and design. Thus came the feedback loop with Kaizen powered small but relentless improvements with jumps in between. Japanese directed these characters first to quality, then to efficiency and then started to deploy it to design and innovation. If you check out Japanese packaging you will realise what I mean.

China too has the same character.

But such character needs inner motivation not CCP herding to come to fore. CCP herding of Chinese entrepreneurship has mitigated many risks and thus expanded the operations driven industries. In time the Chinese will bring artistry and aesthetic to whatever they produce. But that requires freedom, experimentation and failure.

India too is in similar boat.

But India never had the risk moat. In fact, Indian government actively increased the risks for new entrepreneurs. Indians have spent last five decades building safety nets under their families. The risk-taking generation has just burst forth. To help, Indian government is shedding its anti-rich approach and trying to encourage entrepreneurship. Over the next 20 years you will see Indians developing pathways to excellence - trying, failing, succeeding and making a mark on the world.

To achieve that we need to look INTO our own culture. We will need to adapt the global learnings to our way of doing. Our future companies may look totally different. Our employment styles will look totally different from what we see globally. All of those things will need rediscovering, reimagining, innovating and leapfrogging. The next 20 years are going to be super exciting for Indian companies.

We WILL get to excellence.